How Many Deck Boards Do I Need?

Posted by Rick R. on Dec 01, 2023

Building a deck is an exciting home improvement project offering aesthetic and functional benefits. However, one of the most crucial aspects of deck construction is accurately calculating the number of deck boards you'll need. A miscalculation can lead to unnecessary expenses, project delays, or structural issues.

Common challenges include understanding the size of the deck, choosing the right type of decking, and accounting for spacing and waste. This comprehensive guide eliminates the guesswork by providing step-by-step calculations, expert tips, and additional resources to ensure your deck-building project is successful and cost-effective.

Step-by-Step Guide to Calculating Deck Boards

Calculating the number of deck boards you need doesn't have to be a daunting task. Following this step-by-step guide, you can arrive at an accurate estimate, ensuring your project stays on budget and schedule.Simply put, you must calculate the Total deck square footage/board square footage. Still, there is more to consider, such as board length and waste. We’ll cover these considerations in this section.

Determine Deck's Square Footage

The first step is to calculate the total square footage of your deck. Use a tape measure to find the length and width of the deck area and multiply them together.

Formula: Length (ft) x Width (ft) = Total Square FootageExample: For a 20 ft long and 15 ft wide deck, the total square footage would be 300 sq. ft.

Decide on Board Length

Choosing the right board length can help minimize waste. Boards commonly come in sizes of 8, 12, or 16 feet. Consider the layout and dimensions of your deck to choose the most efficient length.

Tips:

- For a 20 ft long deck, 16 ft boards would be efficient with less waste.

- For smaller decks, 8- or 12-foot boards might be more suitable.

Calculate Board Square Footage

Next, calculate the square footage that each board will cover. This is done by multiplying the board's width by its length.

Formula: Board Length (ft) x Board Width (ft) = Board Square FootageExample: For a 16 ft long board that is 6 inches wide, the square footage would be eight sq. ft.

Divide Deck Square Footage by Board Square Footage

Now, divide the total deck square footage by the square footage of a single board to get the needed number.

Formula: Total Deck Square Footage / Board Square FootageExample: 300 sq. ft (Deck) / 8 sq. ft (Board) = 37.5 boards

Account for Spacing, Waste, and Off Cuts

Adding a percentage for spacing between boards, waste, and off-cuts is prudent. A good rule of thumb is to add 10-15% to the total number of boards calculated.

Example: 37.5 boards + 15% = 43.125 boards

Final Calculation and Round-off

Finally, round up to the nearest whole number; you can't purchase a fraction of a board. In this example, you would need 44 boards for your deck project.

By following these steps carefully, you can accurately calculate the number of deck boards you'll need, ensuring a smoother construction process and a more cost-effective project.

Factors Affecting the Number of Deck Boards

Several variables can influence the number of boards you'll need when planning your deck. Let's delve into these factors to help you make an accurate estimate.

Size of the Deck

The total square footage of your deck is the starting point for all calculations. Measure the length and width of your deck and multiply them to get the area.

Case Examples:

- For a 20 ft by 15 ft rectangular deck, the area would be 300 sq. ft.

- For a circular deck with a radius of 10 ft, the area would be approximately 314 sq. ft. (πr²).

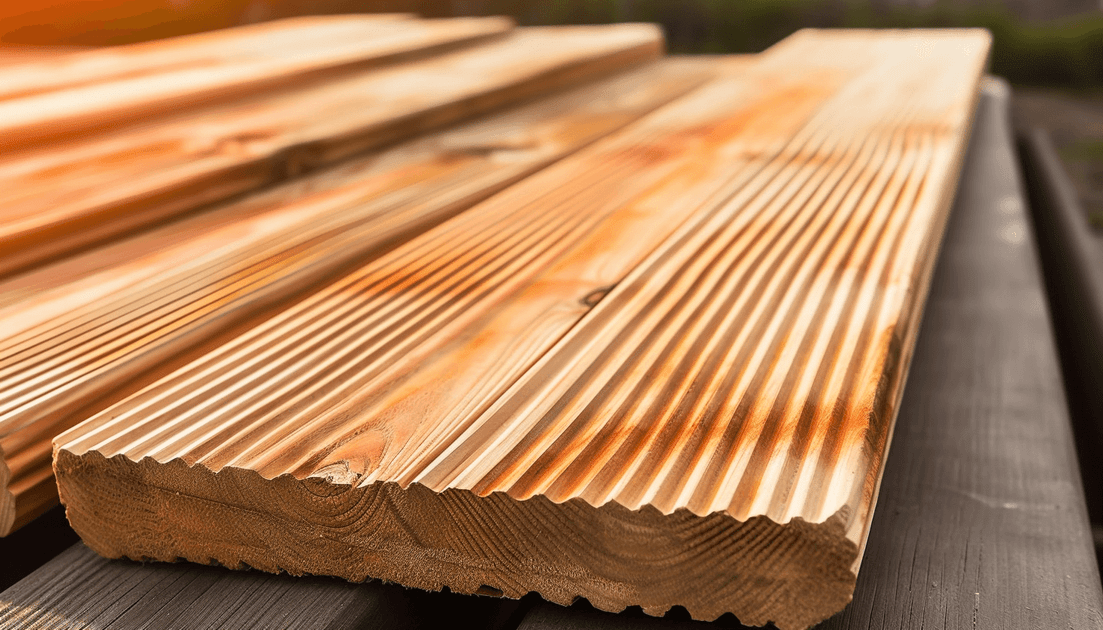

Board Size and Types

Deck boards come in various sizes and materials, affecting the look and the number of boards required.

Common Sizes:

- Nominal sizes like 1x4, 1x6, and 2x6 are standard, but dimensions may vary.

Material Types:

- Pressure-treated lumber is economical but may require frequent maintenance.

- Composite boards are durable but costly.

- Exotic hardwoods like Ipe are visually stunning but expensive.

Spacing Between Deck Boards

Proper spacing is crucial for drainage and material expansion. The spacing varies depending on the material used.

Calculating Spacing:

- For example, if you're using composite boards, a 1/8-inch gap may be required between each board.

Decking Patterns

The layout of your deck boards can also affect the quantity needed. More intricate patterns like diagonal or herringbone will require extra boards.

Waste Factors:

- Straight layout: Add 10% for waste.

- Diagonal layout: Add 15-20% for waste.

Additional Elements

Features like stairs, railings, and multiple levels will also affect your board count.

Tips:

- For stairs, you'll need extra boards for treads and risers.

- For railings, consider the number of balusters and the length of the handrails.

Advanced Considerations

While the basic calculations for determining the number of deck boards are essential, there are advanced considerations that can significantly impact your deck-building project. Overlooking these can lead to delays, increased costs, or even the need for rework.

Frost Lines and Footers

The depth at which water in the soil typically freezes, known as the frost line, can affect the stability of your deck. Footers, or the concrete bases that support the deck's posts, should be set below this line to prevent shifting during freeze-thaw cycles.

Local Building Codes:

- Always refer to local building codes for the frost line depth in your area. For example, the frost line might be 42 inches deep in colder climates, while in warmer areas, it could be as shallow as 12 inches.

Securing Building Permits

Before you start building, it's crucial to secure all necessary permits. Failing to do so can result in fines or even the removal of the constructed deck.

Importance:

- Permits ensure that your deck meets local building codes and safety standards. Experts often require a detailed plan review, providing an additional assurance that your deck is structurally sound.

Special Considerations for Elevated Decks

If your deck is more than a few feet off the ground, additional considerations come into play. These include enhanced structural support, specialized fasteners, and wind load calculations.

Tips:

- Elevated decks often require additional bracing and may need to be anchored to the house's main structure for added stability.

- Consider safety features like railings and balusters, which are usually mandatory for elevated decks.

Tools and Materials Checklist

Before diving into your deck-building project, gathering all the necessary tools and materials is essential. Having everything at hand will save you time and trips to the hardware store, ensuring a smoother construction process.

Tools Needed:

- Tape Measure

- Circular Saw or Miter Saw

- Cordless Drill

- Deck Screws or Hidden Fasteners

- Carpenter's Square

- Level

- Chalk Line

- Safety Gear (gloves, goggles, ear protection)

Materials Needed:

- Deck Boards (as calculated)

- Joists and Beams

- Concrete for Footers

- Ledger Board (if attaching to a house)

- Railings and Balusters (for elevated decks)

- Stain or Sealant

Preparing this checklist in advance sets the stage for a well-organized and efficient deck-building project. Always opt for quality tools and materials to ensure the longevity and safety of your deck.

Why Accurate Calculations Matter

The importance of accurately calculating your project's number of deck boards cannot be overstated. Let's start with the financial aspect. Overestimating the number of boards can lead to unnecessary expenses, as you'll purchase more material than you need. This not only inflates the material costs but also results in storage issues for the surplus. On the flip side, underestimating can be equally problematic. You may need to place additional orders, resulting in color or texture inconsistencies if the new batch of boards doesn't perfectly match the original set.

The timeline of your project is another critical factor affected by miscalculations. Falling short on materials can lead to delays as you wait for additional supplies. This domino effect can push back other scheduled activities, such as staining or sealing the deck and even the final inspection. Labor costs can also escalate if your contractors have to halt work or extend their timeline to accommodate the material shortage.

Final Thoughts on Deck Board Requirements

Building a deck is a rewarding but complex task that requires meticulous planning and accurate calculations. From determining the total square footage of your deck to choosing the right board sizes and types, each step plays a crucial role in the project's success.

Don't overlook advanced considerations like local building codes, frost lines, and the need for permits, especially for elevated decks. With the right tools and materials, you're well on your way to constructing a durable and aesthetically pleasing outdoor space.